Technical room:

Pump unit and elevator control are placed externally, preferably in technical rooms.

Guide tubes for hydraulics:

A guide tube min. Ø80 mm is placed in the pit. The pipes are led directly to the technical room. The location of the pipes is in principle optional, however, the indicated height placement in the pit must be observed. Avoid sharp cracks on the pipe.

Guide pipe for operation / door lock for door:

A route is made for electricity from the technical room or pit to the location of the controls. Preparations are made so that controls can be integrated into the wall.

Tips:

It can be an advantage to make a purchase / pump sump at the bottom of the pit, and possibly reinforce concrete edges with angle steel.

Tolerances:

The length and width of the pit must be observed and tolerance set so that at no point does the pit become smaller than specified. Walls should be perpendicular and linear.

Operation of stair lifts:

At JEMA LIFT, we distinguish between two types of wheelchair users / disabled people:

Group 1: Those who are self-sufficient and can operate the lift themselves

Group 2: Those who need help with the operation

Our stair lift is typically aimed at group 2. The lift is operated by instructed staff, as it is part of the risk assessment (CE marking). It could be a receptionist, a janitor or other staff.

Operating functions require at least the following functions: Lift up, lift down, step up, step down. Placed at level 1.

Contact element is mounted in Ø22.5 mm hole. Installation depth: approx. 40 mm.

Additional features:

Depending on the location of the lift, you can also make a call-in function so that the staff can be called to the lift.

In some situations, a warning signal in the form of light or sound may be necessary when using the lift.

Lift up / down operation on level 2, possibly also on platform.

Switch switch, possibly with key. This can be selected if you want the outsider not to use the lift (eg children or if the lift is located outdoors)

Guideways must be established for cables between controls, switches, signals etc. to the steering.

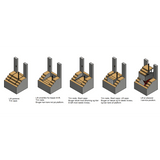

Dimensioning of front plate with pushbuttons:

Our pushbutton switches can be integrated in a profile tube or mounted in a Harmony XAP XAPE30x aluminum front plate, which is screwed to the wall. Remember to install a Harmony XAP_XAPE90x wall box.

The choice of faceplate is determined by the number of features desired.

Delivery and assembly

The price is incl. delivery and assembly

Download brugermanualen her: Brugermanual.pdf

Download the user manual here: User manual.pdf

Laden Sie hier das Benutzerhandbuch herunter: Benutzerhandbuch.pdf